3D construction printing has brought an exciting and profound change in the construction world. The 3D printing in construction comprises the usage of 3D printer attached to an arm which actively builds a project onsite or the usage of printers in a factory which produce building project components that are assembled later. The history of 3D construction printing dates back to 1980s and it became a mainstream technology only in the previous decade. In 3D printing, a software program tells the printer about the dimensions of the end product and the printer inserts material on a platform according to that specific plan.

3D printing makes use of liquid metals, plastics, cement and variety of other materials to form a structure. 3D construction printing is an emblazonry to the global construction arena and a CAD or BIM program tells the 3D printer what it needs to print and machines begin layering out levels of material according to the plan. Many famed construction organizations are leading providers of 3D construction printing services. 3D construction printing became a hot topic of discussion among architects and civil engineers in the previous decade. Dubai municipality office building, UAE, office of the future UAE, and 3D printed houses by Win Sun China are three innovative examples of 3D printing implemented in a construction

- 3D printed house and commercial office designs have numerous benefits including zero-waste construction, time reduction, cost reduction, and support with unusual designs.

- 3D printing is equipped with the potential to cut waste to almost zero and a 3D printer only uses the material required to print the structure.

- It often gets translated into huge savings. 3D printer, power packed with Artificial Intelligence, in construction works on a 24/7/365 basis.

- Construction projects can be completed in a much faster pace with the 3D construction printing. Another great benefit of 3D construction printing is that low skilled labour costs could be avoided.

- One of the fascinating features of 3D printing is its ability to create complex and unusual designs.

- 3D printers can be programmed to create uncommon shapes which would be harder to conceptualize using traditional techniques.

3D construction printing has limitations including costs of research and development and difficulties of integration with other components. The investment needed to use 3D printing designs on a large scale would be enormous and it would be very hard to incorporate a 3D printer into the construction process if the objective is to design a building that incorporates a variety of media.

What is 3D Printing?

3D printing can be used to create concrete structures in a quick and cost-effective manner and it is expected that 3D construction printing will revolutionize the construction industry due to its ability to expedite the industrialization of the construction process. 3D construction printing technology has become a commercial success and it features more intelligent designs and optimized use of materials to the mix. The 3D construction printing leads to built environment with greater sustainability and it is a quick, safe and flexible approach to printing buildings.

Types of Printing

- There are numerous types of 3D printing including stereolithography, selective laser sintering, fused deposition modeling, digital light process, multi jet fusion, polyjet, direct metal laser sintering, and electron beam melting.

- Stereolithography is the original industrial 3D printing process and SLA printers are excellent at producing parts with high level of detail, smooth surface finishes and tight tolerances.

- Selective laser sintering (SLS) melts together nylon based powders into solid plastic and they are suitable for functional testing since SLS parts are made from real thermoplastic material.

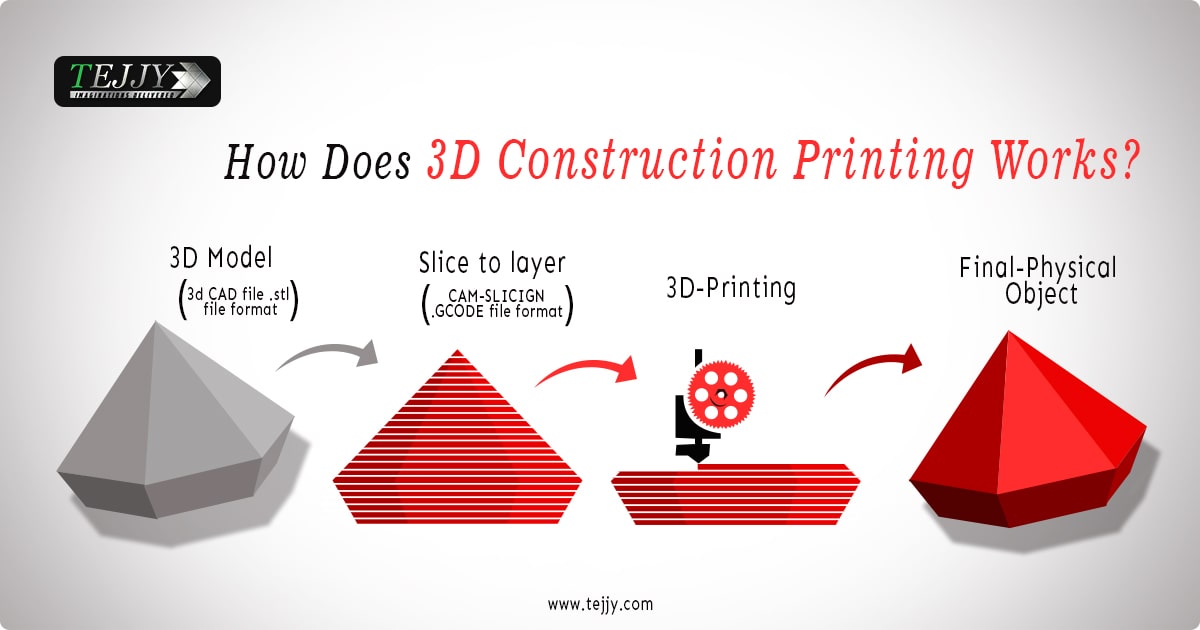

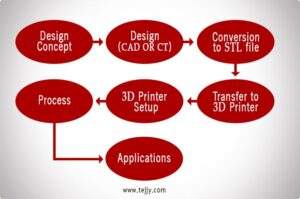

Process of 3D Building Printing

3D printing is a process of making three-dimensional solid objects from digital life and 3D printed object creation is achieved using additive processes. An object is built by laying down successive layers of material until the object is created in an additive process. Each of these layers are a thinly sliced cross section of the object and 5D printing is the opposite of subtractive manufacturing which features cutting out a piece of metal or plastic with a milling machine. Architects can produce complex shapes using less material than traditional manufacturing methods using 3D printing.

Advantages and Disadvantages

- Reduced injury, reduced material costs, quicker construction, cheaper construction, better durability, brand improvement and new markets are the primary advantages of 3D construction printing.

- One of the most important benefits of 3D construction printing will be reduction in injuries within the field.

- Considerable reduction of fabric waste is one of the illustrious advantages of 3D construction printing.

- Limited materials, restricted build size, large volumes, reduction in manufacturing jobs, design inaccuracies, and copyright issues are the disadvantages of 3D construction printing.

- The available selection of raw materials is not exhaustive in 3D printing and it is impossible to recycle many of the printable materials.

- 3D construction printers of today are equipped with small print chambers which restricts the size of parts that can be printed.